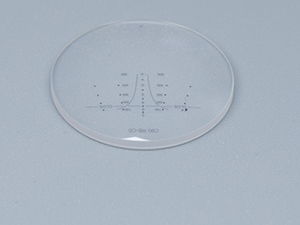

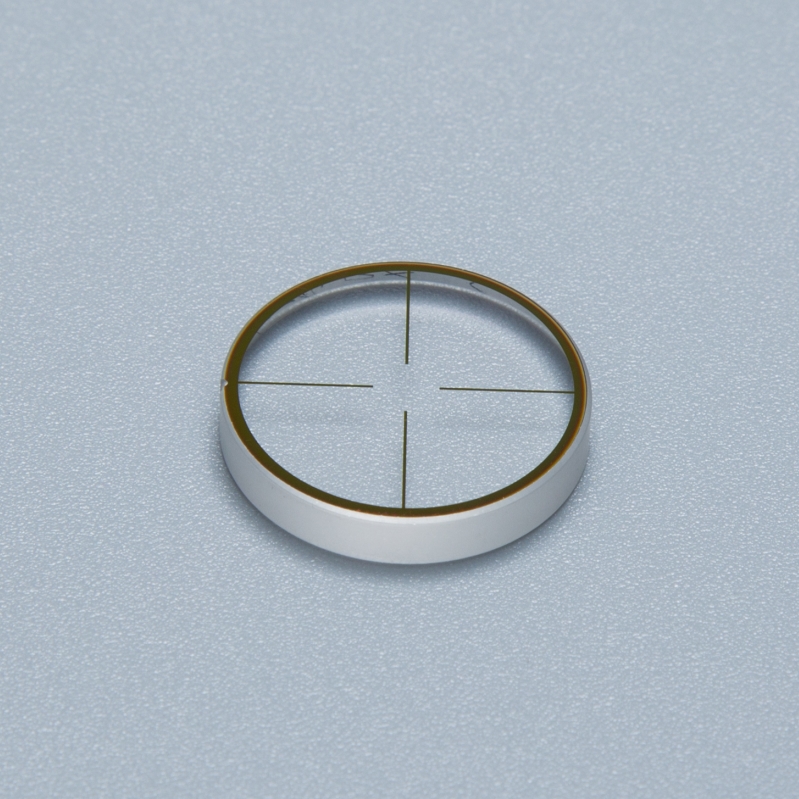

Precision reticles – Chrome on Glass

Product Description

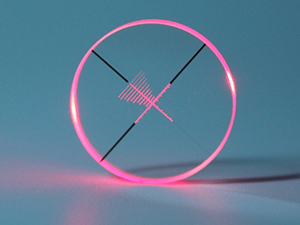

The chrome reticle is a scope reticle that has a reflective coating on the reticle surface. This enhances reticle visibility, especially in low light conditions, by bouncing light off the reticle surface back into the shooter's eyes.

The chrome finish has a mirror-like finish that helps make the crosshairs more visible by increasing the amount of light available. The result is brighter, sharper markings that are more visible in low light conditions.

However, chrome markings can have some drawbacks. For example, they may cause glare or reflections in certain lighting conditions, which may distract or interfere with the shooter's ability to see the target clearly. Also, a chrome coating may add to the cost of a rifle scope.

Overall, the chrome reticle is a good choice for the shooter who regularly hunts or shoots in low light conditions, but it is important to consider other factors such as the quality of the rifle scope when choosing the right model , design and price.

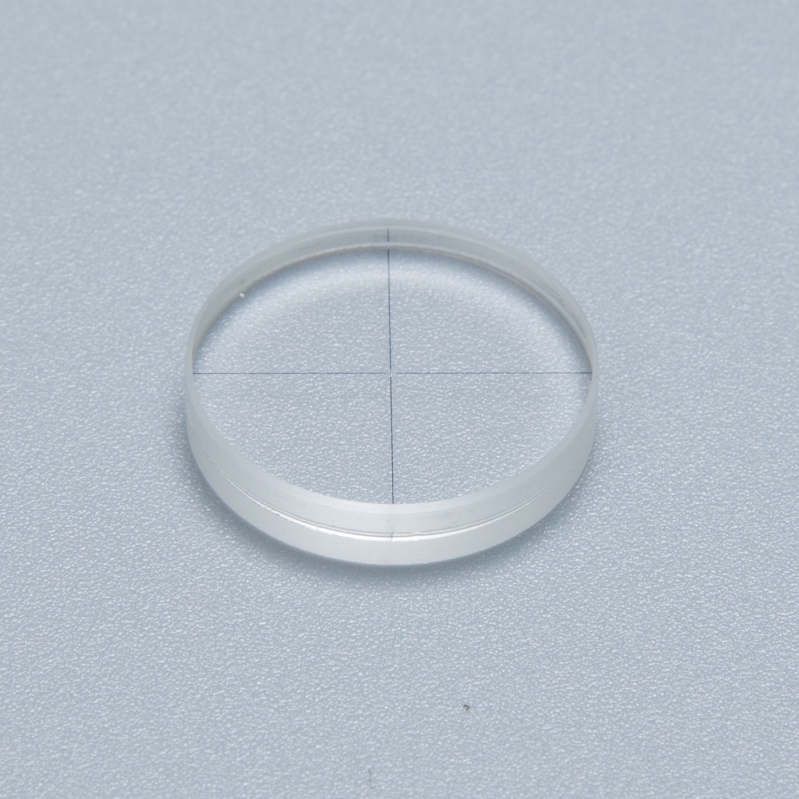

Precision reticles are key components in the manufacture of various optical instruments and equipment. They require a high level of precision and accuracy to perform tasks effectively. These reticles are basically patterns etched into the glass substrate. Among other applications, they are used for alignment, calibration and measurement of various high-precision industrial and scientific equipment.

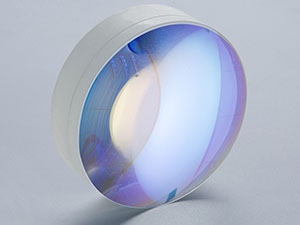

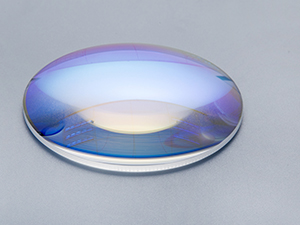

To ensure maximum clarity and precision, the glass substrate used for the reticle needs to be chromed using a special process. The chrome finish enhances the contrast of the pattern, clearly delineating it from the background for optimal visibility and accuracy. The chrome layer can achieve high-resolution images by controlling the diffraction of light from the glass surface.

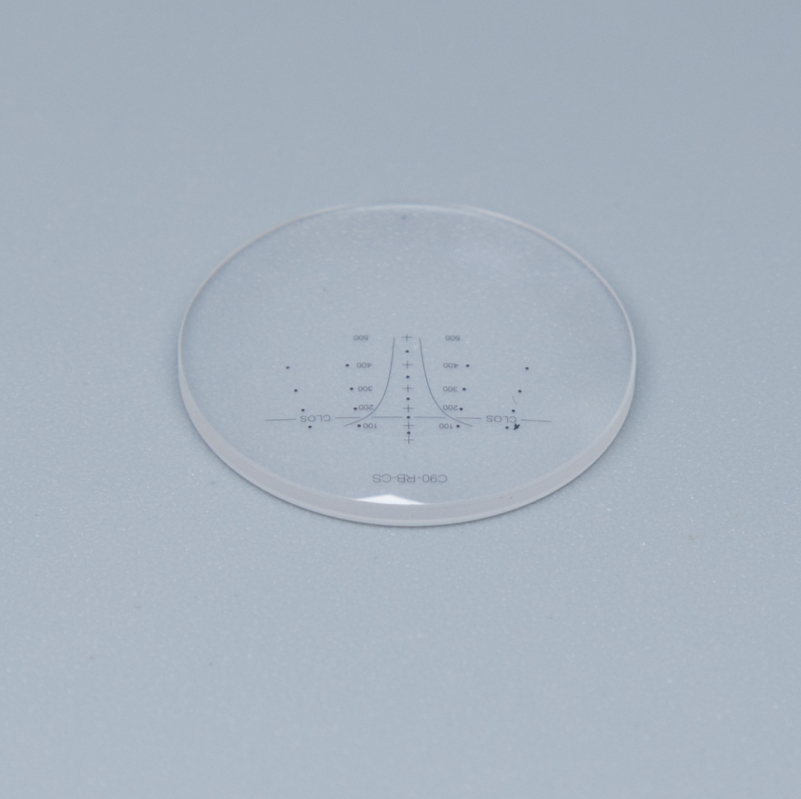

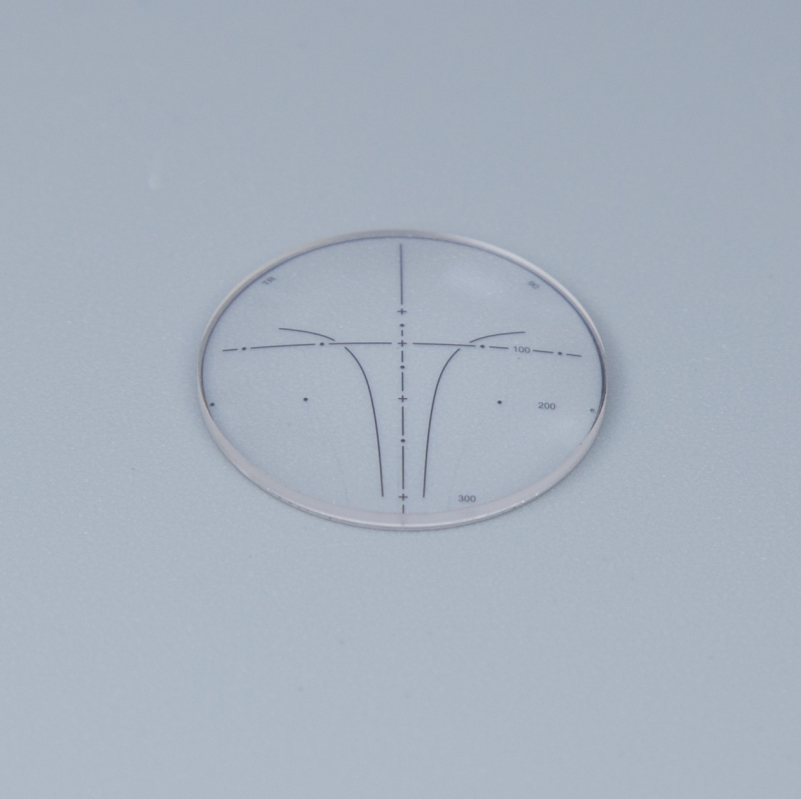

There are different types of reticles, each designed for a specific application, such as reticles and slot reticles. Reticles or Crosshairs (A reticule consists of two lines that intersect to form a crosshair). They are commonly used to align and align optical instruments such as microscopes, telescopes and cameras. Slot reticles, on the other hand, are etched with a series of parallel lines or patterns for spatial measurement. They can help determine the precise location of objects very accurately.

Precision reticles can be customized to meet the specific requirements of various applications, such as different shapes, sizes and patterns. For example, some applications may require a reticle with high contrast, while other applications may require high precision without worrying about contrast or resolution.

Precision marking lines are becoming increasingly important in numerous industries including semiconductor, biotechnology and aerospace. As the demand for high-precision equipment grows, so does the need for high-quality precision reticles. As technology advances, mask designs become more complex, requiring manufacturers to invest in state-of-the-art equipment and techniques to maintain tight tolerances and achieve the required level of precision.

In conclusion, precision marking lines play a vital role in a range of high precision industries. Coatings, such as chrome on glass, contribute to this reliability, while also improving our quality of life. As the demand for high-precision instruments continues to grow, the need for precision reticles will only become more important.

Specifications

|

Substrate |

B270 /N-BK7 / H-K9L |

|

Dimensional Tolerance |

-0.1mm |

|

Thickness Tolerance |

±0.05mm |

|

Surface Flatness |

3(1)@632.8nm |

|

Surface Quality |

20/10 |

|

Line Width |

Minimum 0.003mm |

|

Edges |

Ground , 0.3mm max. Full width bevel |

|

Clear Aperture |

90% |

|

Parallelism |

<30” |

|

Coating |

Single Layer MgF2, Ravg<1.5%@Design Wavelength |

|

Line/Dot/Figure |

Cr or Cr2O3 |