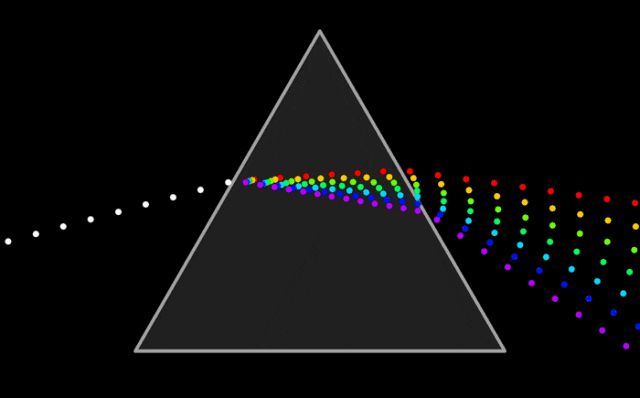

Prism is an optical element that refracts light at specific angles based on its incident and exit angles. Prisms are primarily used in optical systems to change the direction of light paths, produce image inversions or deflections, and enable scanning functions.

Prisms used to change the direction of light beams can generally be divided into reflecting prism and refracting prism

Reflecting prisms are made by grinding one or more reflective surfaces on a piece of glass using the principle of total internal reflection and coating technology. Total internal reflection occurs when light rays from inside the prism reach the surface at an angle greater than the critical angle for total internal reflection, and all light rays are reflected back inside. If total internal reflection of the incident light cannot occur, a metallic reflective coating, such as silver, aluminum, or gold, needs to be deposited on the surface to reduce the loss of light energy on the reflective surface. In addition, in order to increase the transmittance of the prism and reduce or eliminate stray light in the system, anti-reflection coatings in a specific spectral range are deposited on the inlet and outlet surfaces of the prism.

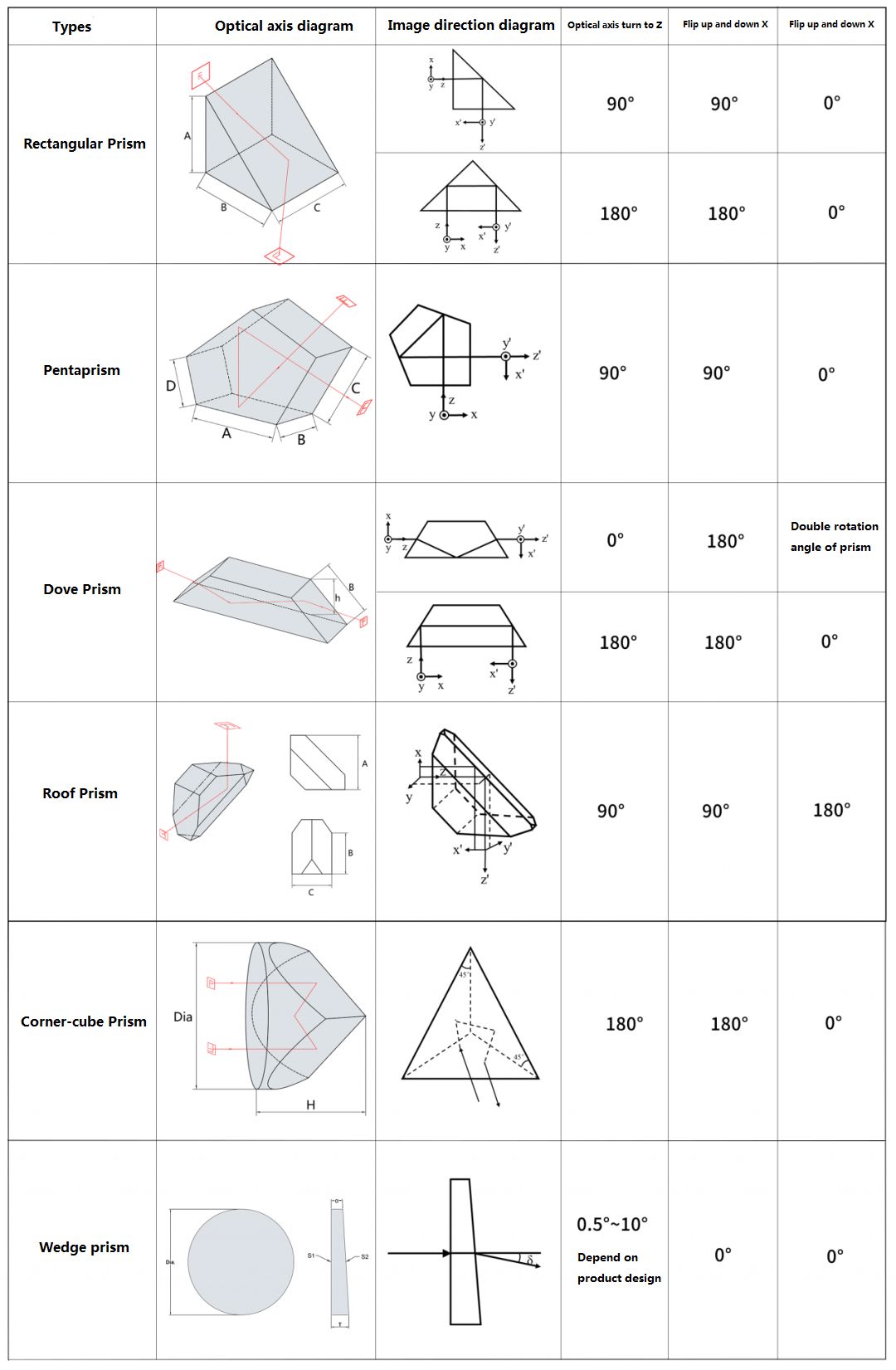

There are many types of reflective prisms in various shapes. Generally, it can be divided into simple prisms (such as right-angle prism, pentagonal prism, Dove prism), roof prism, pyramid prism, compound prism, etc.

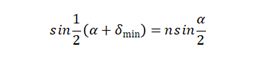

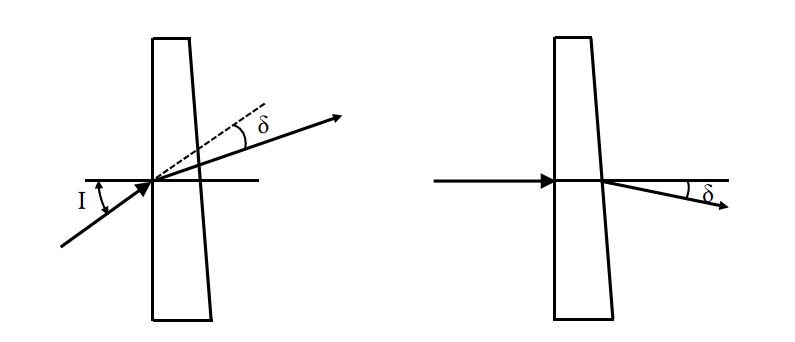

Refracting prisms are based on the principle of light refraction. It consists of two refractive surfaces, and the line formed by the intersection of the two surfaces is called the refractive edge. The angle between the two refracting surfaces is called the refraction angle of the prism, represented by α. The angle between the outgoing ray and the incident ray is called the deviation angle, represented by δ. For a given prism, the refraction angle α and refractive index n are fixed values, and the deflection angle δ of the refractive prism only changes with the incident angle I of the light ray. When the optical path of the light is symmetrical with the refracting prism, the minimum value of the deflection angle is obtained, and the expression is:

The optical wedge or wedge prism is referred to as a prism with an extremely small refraction angle. Due to the negligible refraction angle, when light is incident vertically or nearly vertically, the expression for the deviation angle of the wedge can be approximately simplified as: δ = (n-1) α.

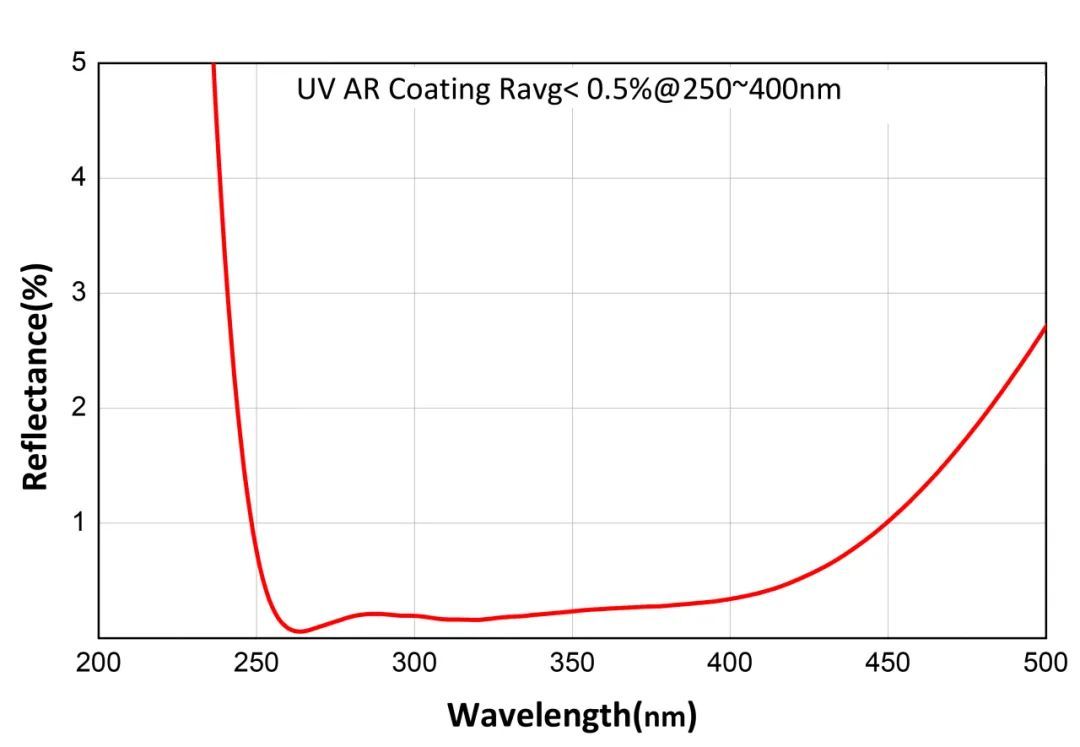

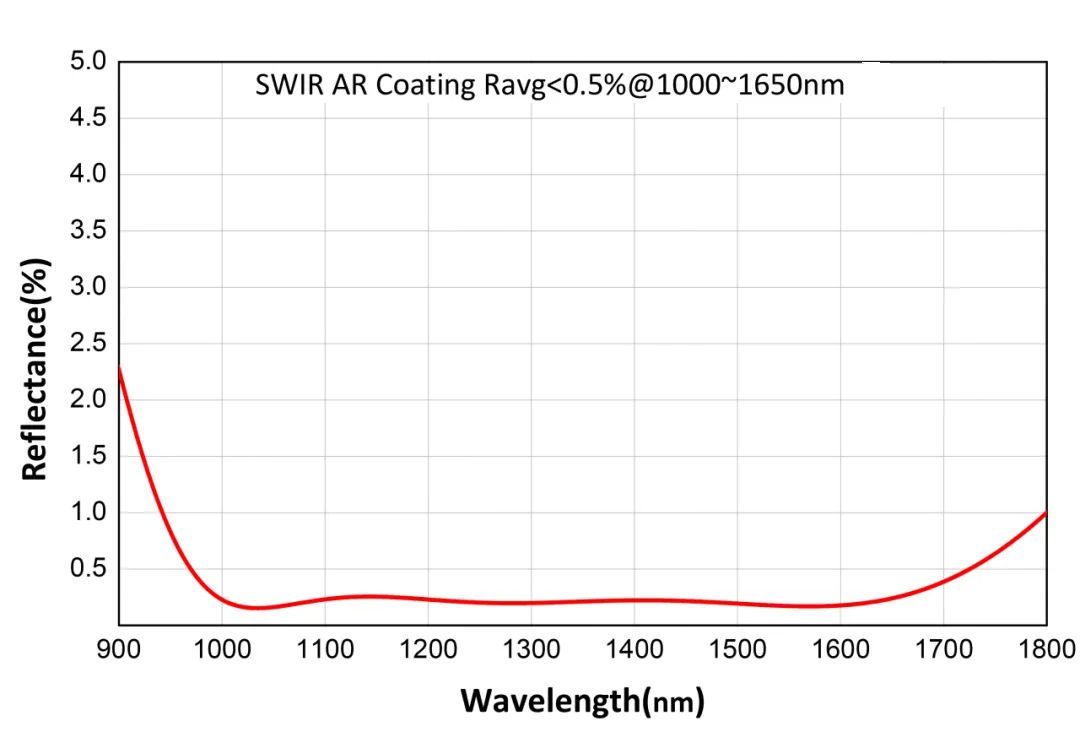

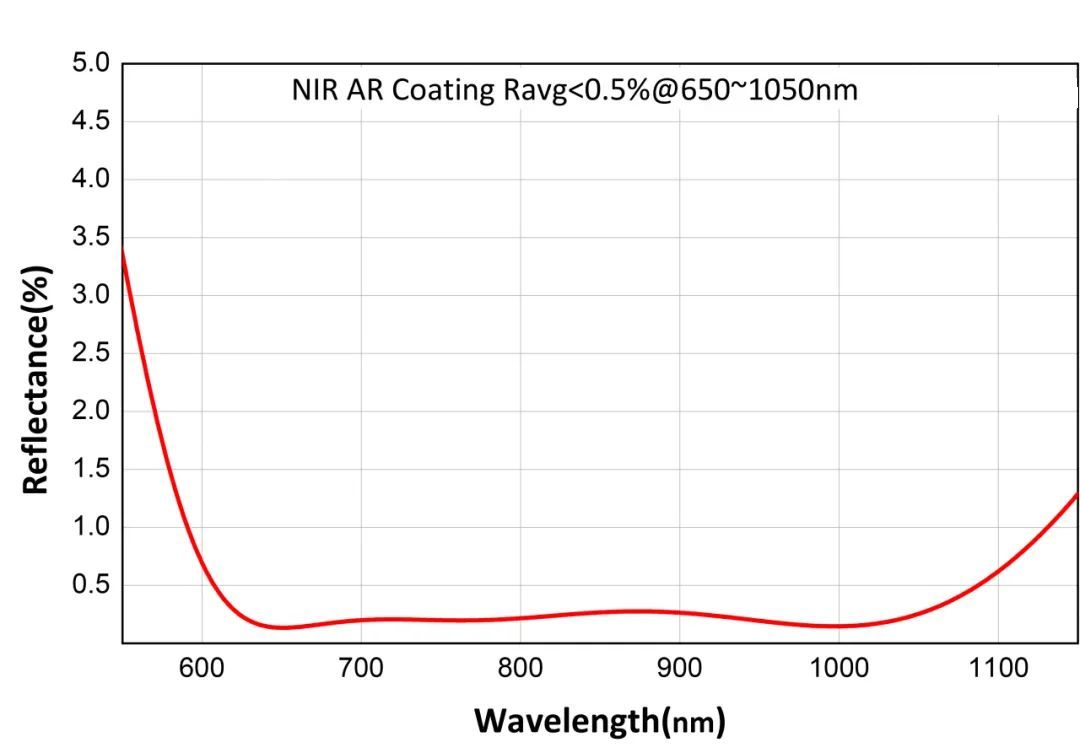

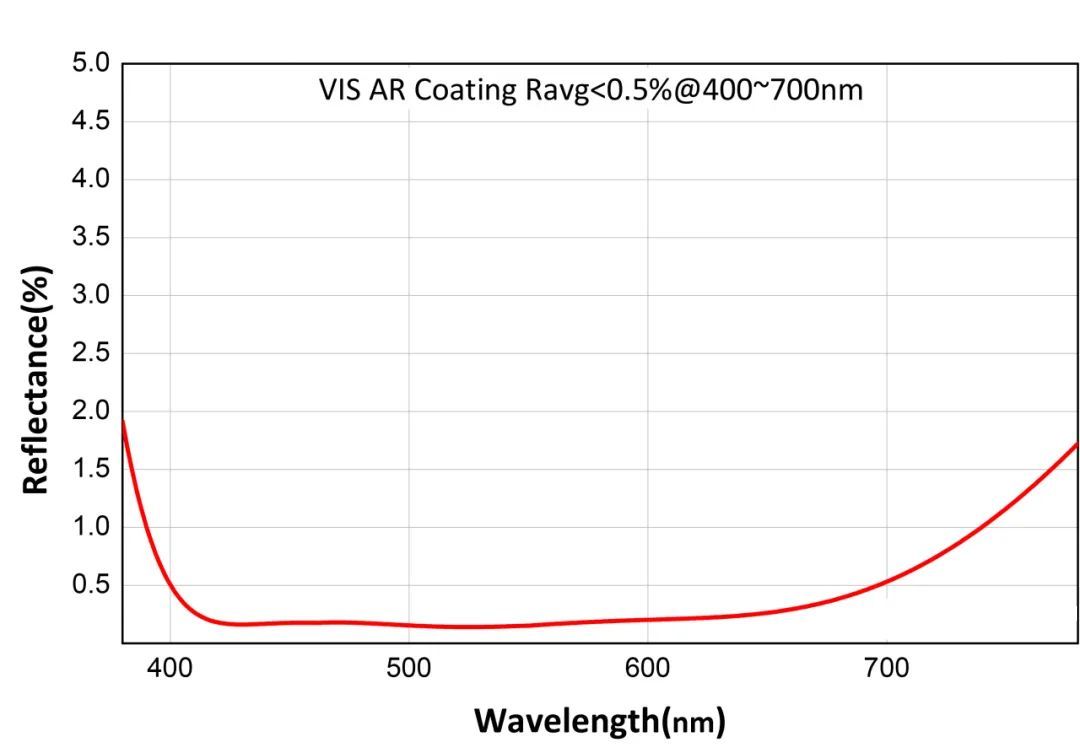

Coating characteristics:

Typically, aluminum and silver reflective films are applied onto the prism’s reflector surface to enhance light reflectivity. Anti-reflection films are also coated on the incident and exit surfaces to increase light transmittance and minimize stray light across various UV, VIS, NIR, and SWIR bands.

Application fields: Prisms find extensive applications in digital equipment, scientific research, medical instruments, and other domains. – Digital equipment: cameras, closed-circuit TVs (CCTVs), projectors, digital cameras, digital camcorders, CCD lenses, and various optical devices. – Scientific research: telescopes, microscopes, levels/focusers for fingerprint analysis or gun sights; solar converters; measuring instruments of diverse types. – Medical instruments: cystoscopes/gastroscopes as well as different laser treatment equipment.

Jiujon Optics offers a range of prism products such as right-angle prisms made from H-K9L glass or UV fused quartz. We provide pentagon prisms, Dove prisms, Roof prisms, corner-cube prisms, UV fused silica corner-cube prisms, and wedge prisms suitable for ultraviolet (UV), visible light (VIS), near-infrared (NIR) bands with varying precision levels.

These products are coated like aluminum/silver/gold reflection film/anti-reflection film/nickel-chromium protection/black paint protection.

Jiujon offers customized prism services tailored to your specific requirements. This includes modifications in size/parameters/coating preferences etc. Feel free to contact us for further details.

Post time: Nov-20-2023