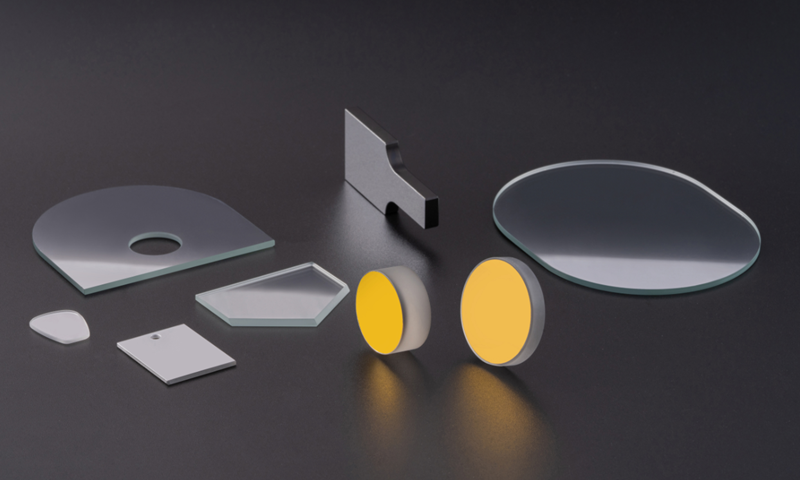

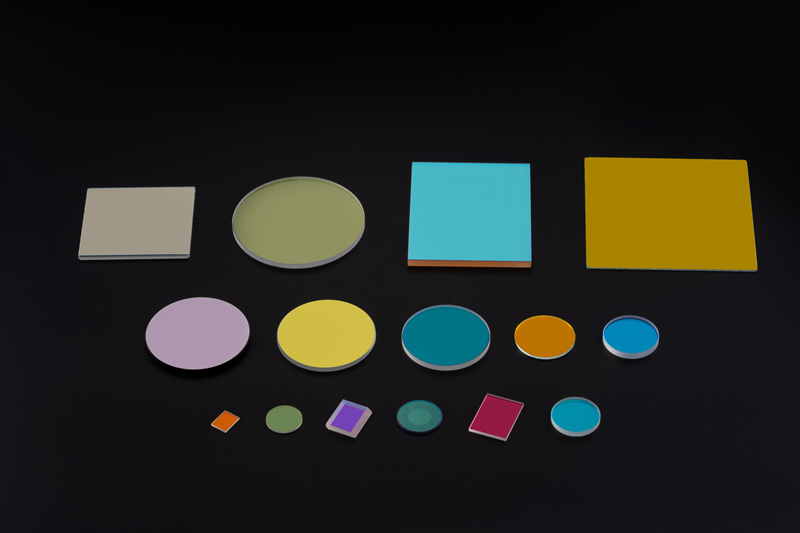

Optical elements, as devices that can manipulate light, control the direction of light wave propagation, intensity, frequency and phase of light, and play a vital role in laser processing equipment. They are not only the basic components of the laser processing system, but also the An important part of the system. An important driving force for the continuous development of laser processing technology. The application and role of optical components in laser processing equipment will be explained below:

Application of optical components in equipment

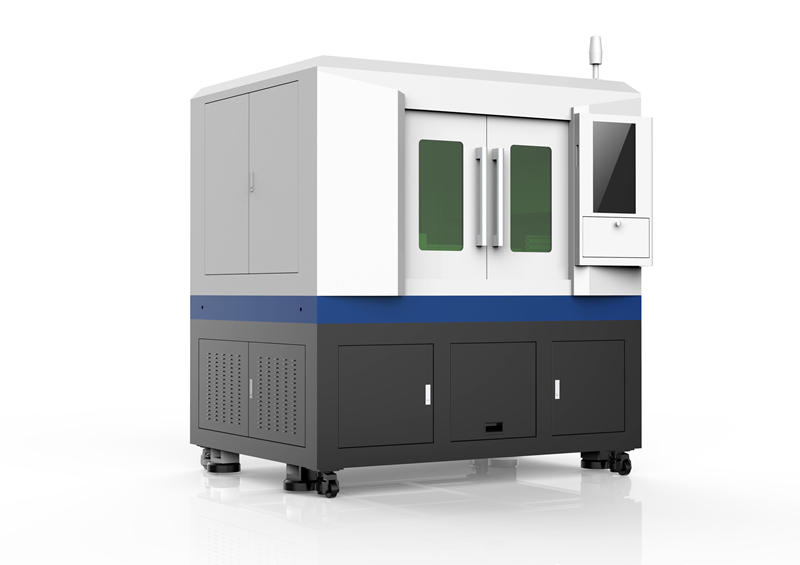

01 Laser cutting machine

Optical components used: Focusing lens, Mirror etc.

Application scenario: used for precision cutting of metal, non-metal and other materials.

02 laser-beam welding machineaser- beam welding machine

Optical components used: focusing lens, beam expander, etc.;

Application scenario: Used to punch small and precise holes in materials, such as electronic components and medical devices.

Application scenario: Used to punch small and precise holes in materials, such as electronic components and medical devices

03 laser-beam drilling machine

Optical components used: focusing lens, beam expander, etc.;

Application scenario: Used to punch small and precise holes in materials, such as electronic components and medical devices.

04 laser marking machine

Optical components used: scanning mirrors, filters, etc.;

Application scenario: Used to mark text, patterns, QR codes and other information on the surface of electronic products, packaging materials and other materials.

05 Laser etching machine

Optical components used: focusing lens, polarizer, etc.;

Application scenario: used for fine etching on the surface of integrated circuits, optical components and other materials.

The function of optical components

01 Improve processing accuracy

Optical components can precisely control the shape, direction and energy distribution of the laser beam, enabling high-precision processing. For example, a focusing lens can concentrate a laser beam into a small spot, enabling high-precision cutting and welding.

02 Improve processing efficiency

By optimizing the configuration of optical components, fast scanning and precise control of the laser beam can be achieved, thereby improving processing efficiency. For example, laser scanning mirrors can quickly change the direction of a laser beam, allowing for rapid cutting and drilling of materials.

03 Ensure processing quality

Optical components can maintain the stability and consistency of the laser beam and ensure the stability and reliability of processing quality. For example, filters can eliminate stray light, increase the purity of the laser beam, and improve processing results.

04 Expand processing scope

By replacing or adjusting optical components, the processing requirements of different materials, thicknesses, and shapes can be met. For example, by adjusting the focal length of the focusing lens, cutting and welding of materials of different thicknesses can be achieved.

05 Keep your equipment safe

Optical components protect lasers and processing equipment from damage caused by laser beams. For example, mirrors and beam expanders can direct the laser beam into the processing area, preventing direct exposure of the laser beam to the laser and other parts of the equipment.

To sum up, optical components play a vital role in laser processing equipment. They not only improve processing accuracy and efficiency, ensure processing quality, but also expand processing scope and ensure equipment safety. Therefore, when designing and using laser processing equipment, factors such as the selection, configuration, and optimization of optical components must be fully considered.

Post time: Nov-07-2024