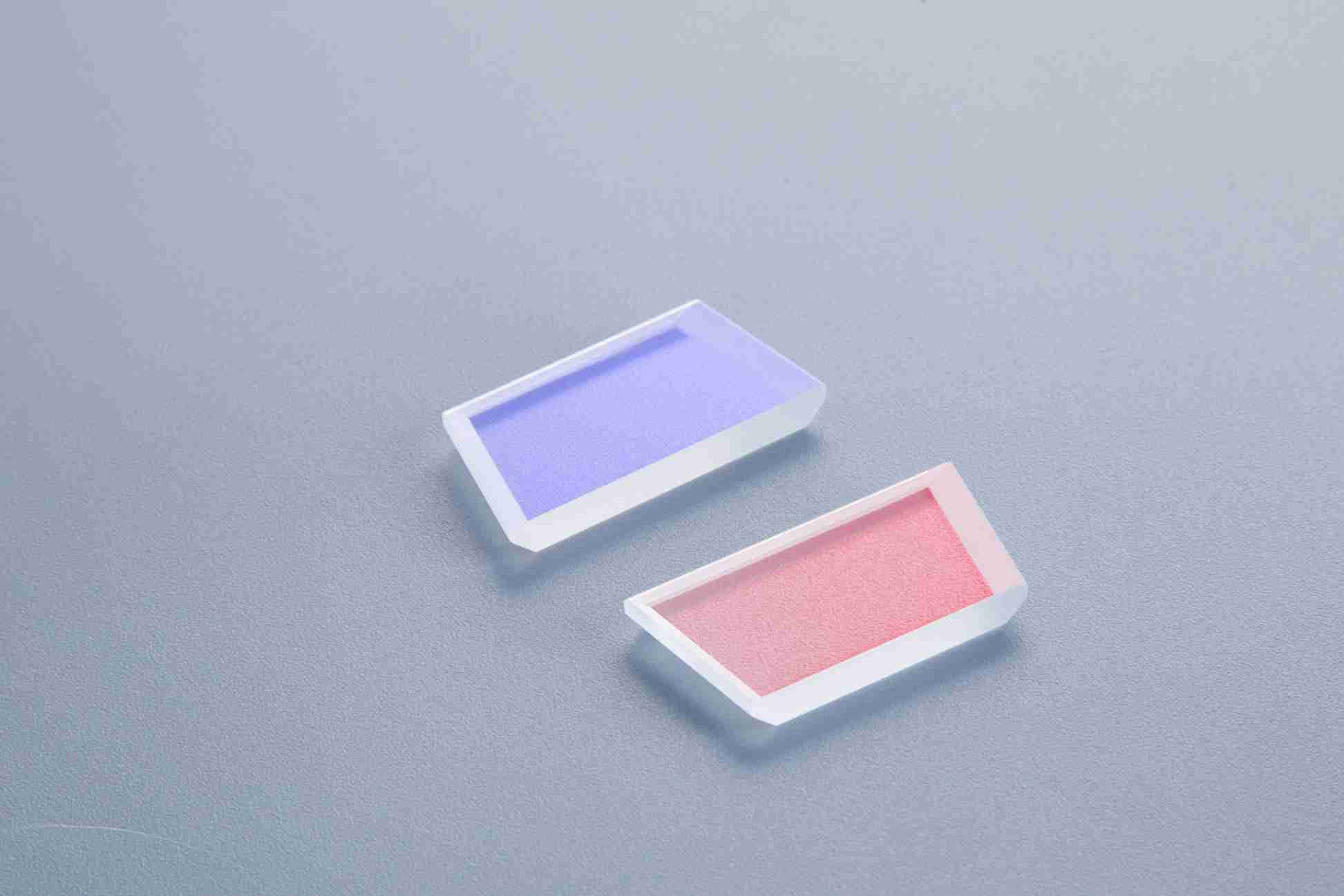

Assembled Window for Laser Level Meter

Product Description

The assembled optical window is an important part of the laser level for measuring distance and height using high precision laser technology. These windows are usually made of a high-precision optical window. The main function of the optical window is to allow the laser beam to pass through and provide a clear and unobstructed view of the target surface. To achieve this, the surface of the optical window should be polished and smooth with minimal surface roughness or imperfections that could interfere with laser transmission. Any impurities or air bubbles present in the optical window may cause inaccurate readings or compromise data quality. To ensure optimum performance of glued optical windows, they must be properly secured to the laser level using a high quality adhesive material. Bonding the optical windows to the laser level ensures a secure connection and prevents it from being accidentally knocked out of alignment or shifted. This is especially important in harsh or rugged environments where devices are exposed to vibration, extreme temperatures, and other types of physical stress that can damage or loosen the optical window. Most bonded optical windows for laser levels are equipped with an anti-reflective (AR) coating that helps minimize or eliminate unwanted reflections of the laser light from the window surface. The AR coating increases the transmission of light through the optical window, thereby enhancing the performance of the laser level and helping to produce more accurate and reliable measurements. When selecting a assembled optical window for a laser level, factors such as the size and shape of the window, the bonding material, and the environmental conditions in which the device will be used need to be considered. In addition, it must be ensured that the optical window is compatible with the specific type and wavelength of laser light used in the device. By selecting and properly installing the correct glued optical window, laser level operators can achieve optimum performance and high precision in their surveying tasks.

Specifications

|

Substrate |

B270 / Float Glass |

|

Dimensional Tolerance |

-0.1mm |

|

Thickness Tolerance |

±0.05mm |

|

TWD |

PV<1 Lambda @632.8nm |

|

Surface Quality |

40/20 |

|

Edges |

Ground , 0.3mm max. Full width bevel |

|

Parallelism |

<10” |

|

Clear Aperture |

90% |

|

Coating |

Rabs<0.5%@Design Wavelength, AOI=10° |