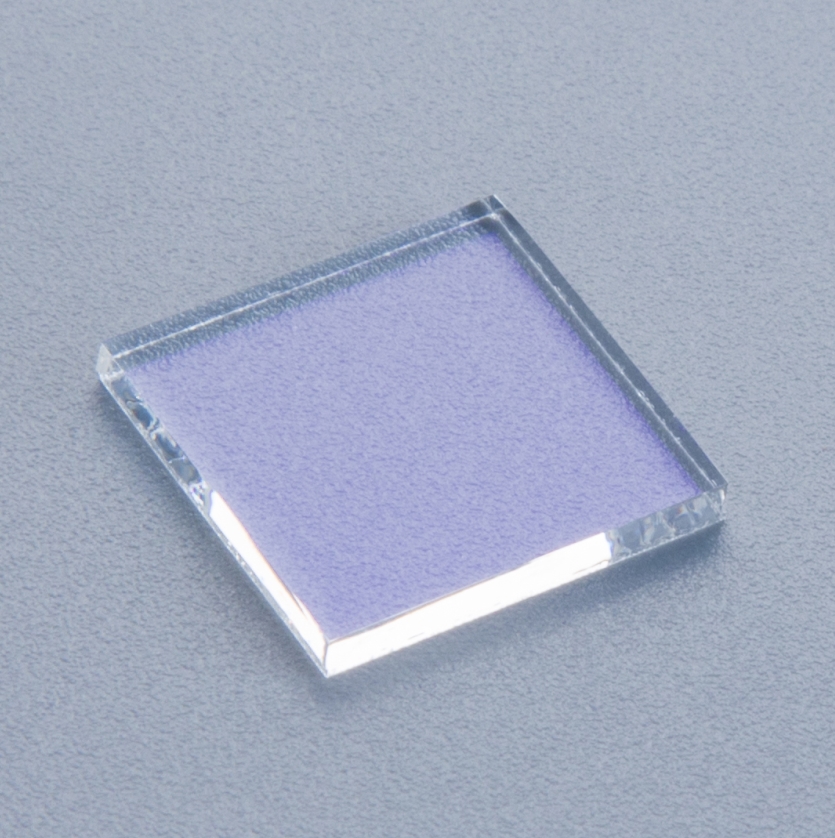

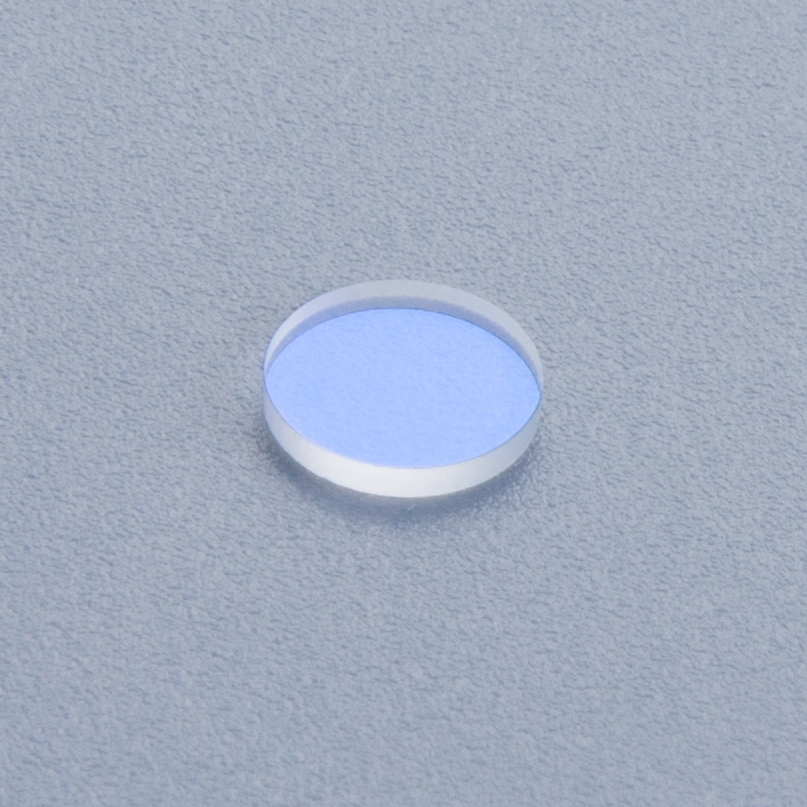

Anti-Reflect Coated on Toughened Windows

Product Description

An anti-reflective (AR) coated window is an optical window that has been specially treated to reduce the amount of light reflection that occurs on its surface. These windows are used in a variety of fields, including aerospace, automotive, and medical applications, where clear and accurate transmission of light is critical.

AR coatings work by minimizing the reflection of light as it passes through the surface of the optical window. Typically, AR coatings are applied in thin layers of materials, such as magnesium fluoride or silicon dioxide, that are deposited on the window surface. These coatings cause a gradual change in the refractive index between the air and the window material, reducing the amount of reflection that occurs on the surface.

The benefits of AR coated windows are many. First, they increase the clarity and transmission of light passing through the window by reducing the amount of light reflected from surfaces. This produces a clearer and sharper image or signal. In addition, AR coatings provide higher contrast and color accuracy, making them useful in applications such as cameras or projectors that require high-quality image reproduction.

AR-coated windows are also useful in applications where light transmission is critical. In these cases, light loss due to reflection can significantly reduce the amount of light reaching the desired receiver, such as a sensor or photovoltaic cell. With AR coating, the amount of reflected light is minimized for maximum light transmission and improved performance.

Finally, AR coated windows also help reduce glare and improve visual comfort in applications such as automotive windows or glasses. Reduced reflections minimize the amount of light scattered into the eye, making it easier to see through windows or lenses.

In summary, AR-coated windows are an important component in many optical applications. The reduction in reflection results in improved clarity, contrast, color accuracy and light transmission. AR-coated windows will continue to grow in importance as technology continues to advance and the need for high-quality optics increases.

Specifications

| Substrate | Optional |

| Dimensional Tolerance | -0.1mm |

| Thickness Tolerance | ±0.05mm |

| Surface Flatness | 1(0.5)@632.8nm |

| Surface Quality | 40/20 |

| Edges | Ground , 0.3mm max. Full width bevel |

| Clear Aperture | 90% |

| Parallelism | <30” |

| Coating | Rabs<0.3%@Design Wavelength |